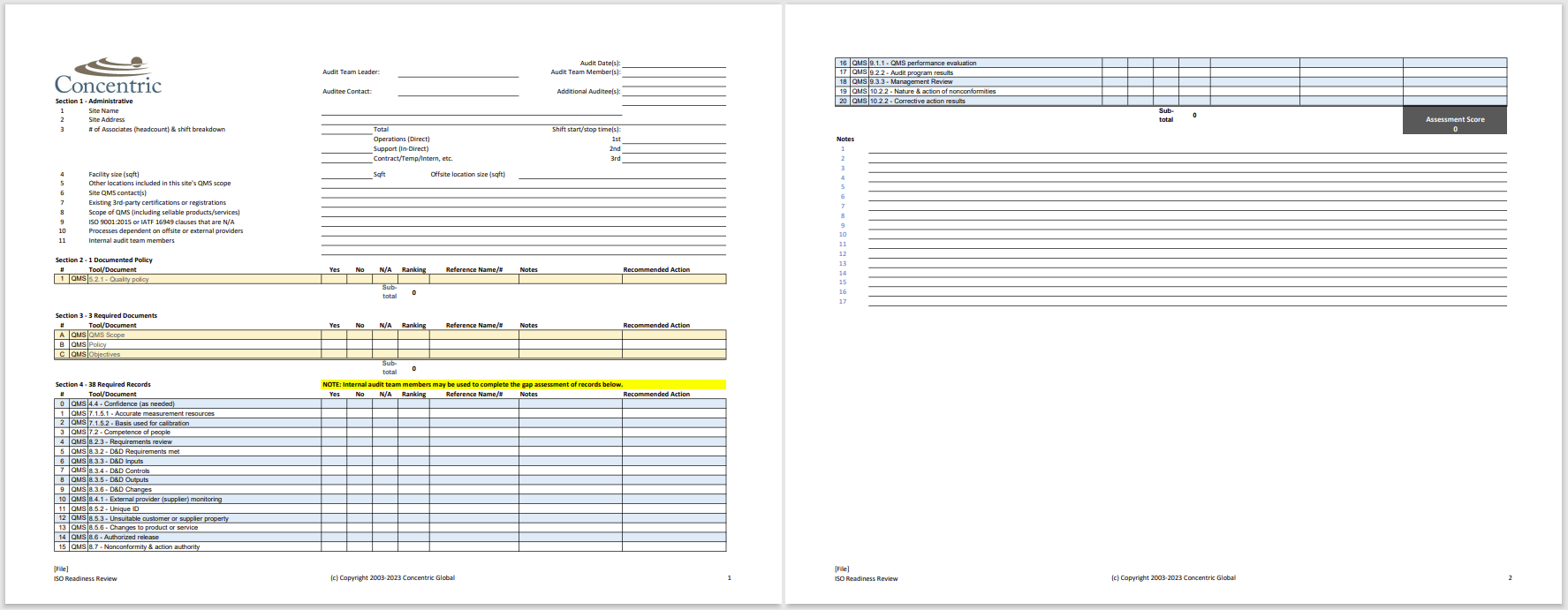

38 Required Records of ISO 9001:2015 (20) and IATF 16949:2016 (18)

UPDATED 2/22/23: ISO 9001:2015 has changed several terms and definitions. One of the key terms with the latest version is “documented information”, which I find to be confusing and unnecessary. With a focus to ensure service industry organizations feel included (i.e. they buy copies of the ISO 9001 standard), ISO/TC 176 uses the term documented information to include what was previously referred to as documented procedures, records and other documentation.

In ISO 9001:2008 and 2000, the practitioners could use the terms “(see 4.2.4)” and the word “record” to easily spot where there was a record requirement to be fulfilled. That indicator is no longer in the standard, so we’ve extracted all of the record requirements below.

QMS - ISO 9001:2015

0 4.4 - Confidence (as needed)

1 7.1.5.1 - Accurate measurement resources

2 7.1.5.2 - Basis used for calibration

3 7.2 - Competence of people

4 8.2.3.2 - Requirements review

5 8.3.2 - D&D Requirements met

6 8.3.3 - D&D Inputs

7 8.3.4 - D&D Controls

8 8.3.5 - D&D Outputs

9 8.3.6 - D&D Changes

10 8.4.1 - External provider (supplier) monitoring

11 8.5.2 - Unique ID

12 8.5.3 - Unsuitable customer or supplier property

13 8.5.6 - Changes to product or service

14 8.6 - Authorized release

15 8.7 - Nonconformity & action authority

16 9.1.1 - QMS performance evaluation

17 9.2.2 - Audit program results

18 9.3.3 - Management Review

19 10.2.2 - Nature & action of nonconformities

20 10.2.2 - Corrective action results

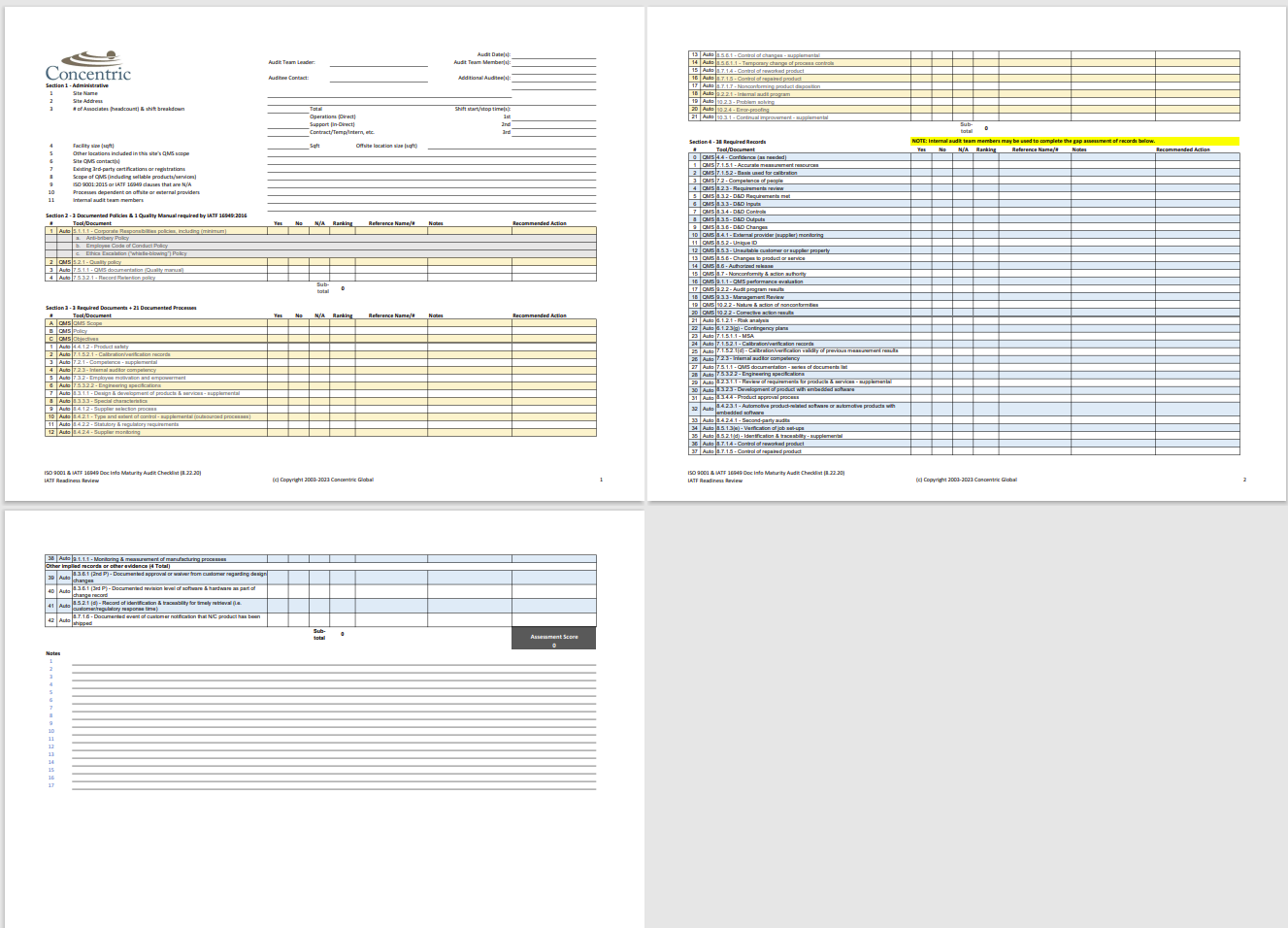

IATF 16949:2016 builds on the records requirements by adding 18 more records at a minimum that must be retained.

Automotive QMS – IATF 16949

21 6.1.2.1 - Risk analysis

22 6.1.2.3(g) - Contingency plans

23 7.1.5.1.1 - MSA

24 7.1.5.2.1 - Calibration/verification records

25 7.1.5.2.1(d) - Calibration/verification validity of previous measurement results

26 7.2.3 - Internal auditor competency

27 7.5.1.1 - QMS documentation - series of documents list

28 7.5.3.2.2 - Engineering specifications

29 8.2.3.1.1 - Review of requirements for products & services - supplemental

30 8.3.2.3 - Development of product with embedded software

31 8.3.4.4 - Product approval process

32 8.4.2.3.1 - Automotive product-related software or automotive products with embedded software

33 8.4.2.4.1 - Second-party audits

34 8.5.1.3(e) - Verification of job set-ups

35 8.5.2.1(d) - Identification & traceability - supplemental

36 8.7.1.4 - Control of reworked product

37 8.7.1.5 - Control of repaired product

38 9.1.1.1 - Monitoring & measurement of manufacturing processes

Additional Records implied in IATF 16949

39 8.3.6.1 (2nd P) - Documented approval or waiver from customer regarding design changes

40 8.3.6.1 (3rd P) - Documented revision level of software & hardware as part of change record

41 8.5.2.1 (d) - Record of identification & traceability for timely retrieval (i.e. customer/regulatory response time)

42 8.7.1.6 - Documented event of customer notification that N/C product has been shipped